T84 neutral synchro hub position

-

Finn42

- Sergeant Major of the Gee

- Posts: 349

- Joined: Thu Jan 06, 2005 5:40 pm

- Location: Santa Rosa, CA

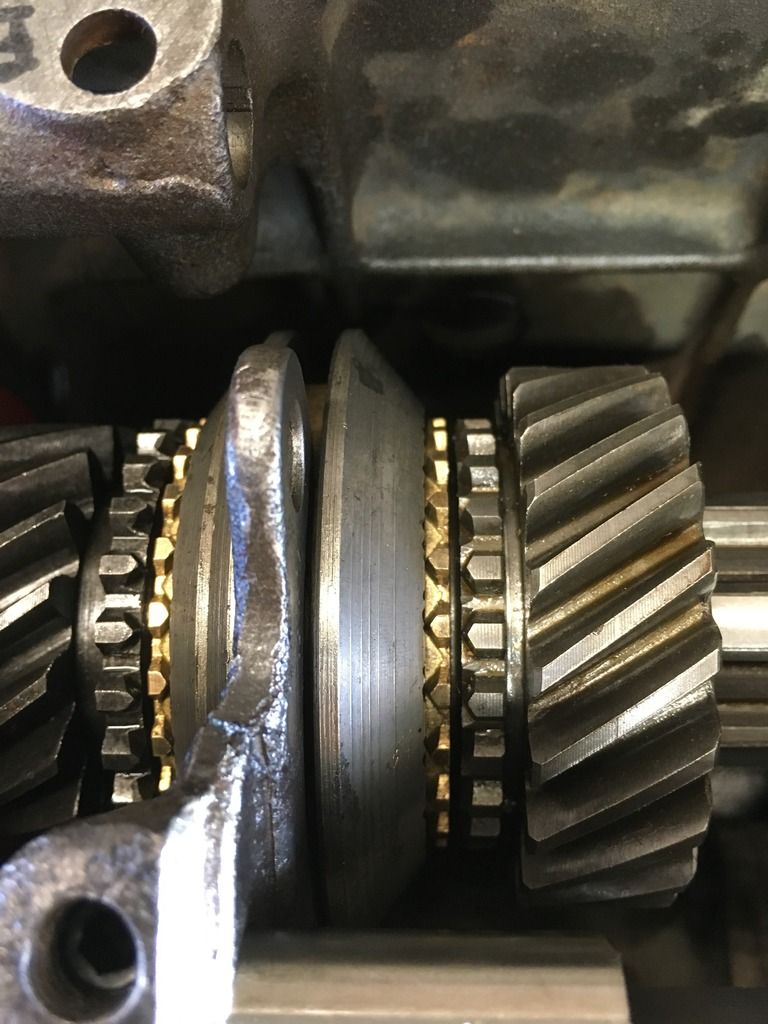

T84 neutral synchro hub position

Hello to all

Finishing up a t84 build. I have good baulking ring play, achieved by shimming and removing my slinger. My input shaft has an original snap ring albeit I had to forgo using a seal because the snout is level with the clip.

Ok! With everything assembled and rear nut torqued and the old t18 bolted up: the 2/3 shift fork wants to just slightly contact the synchro hub groove edge in neutral. It is touching at the front edge of the groove. I noticed the synchro hub when spun is not “true”. The groove touches and then doesn’t. I’m going to try a different one. Regardless, is this slight contact ok? And is there a way to fix it?

I’ve read at length all the t84 threads and I have a good grasp on the t84, but this one has me stumped.

I tried shimming the main shaft more to move the synchro forward, but it bound up the 3rd gear baulking ring.

Finishing up a t84 build. I have good baulking ring play, achieved by shimming and removing my slinger. My input shaft has an original snap ring albeit I had to forgo using a seal because the snout is level with the clip.

Ok! With everything assembled and rear nut torqued and the old t18 bolted up: the 2/3 shift fork wants to just slightly contact the synchro hub groove edge in neutral. It is touching at the front edge of the groove. I noticed the synchro hub when spun is not “true”. The groove touches and then doesn’t. I’m going to try a different one. Regardless, is this slight contact ok? And is there a way to fix it?

I’ve read at length all the t84 threads and I have a good grasp on the t84, but this one has me stumped.

I tried shimming the main shaft more to move the synchro forward, but it bound up the 3rd gear baulking ring.

Last edited by Finn42 on Mon Apr 16, 2018 7:21 am, edited 2 times in total.

1942 GPW

1942 T2 wla

1942 Bantam

1942 WC40

1941 Nash-kelvinator Ben hur

1943 Ben Hur

1944 Ben hur

1942 T2 wla

1942 Bantam

1942 WC40

1941 Nash-kelvinator Ben hur

1943 Ben Hur

1944 Ben hur

-

dinof

- G-Major General

- Posts: 2862

- Joined: Fri Jan 08, 2010 4:32 pm

- Location: Arcadia & Johannesburg Ca.

Re: T84 neutral synchro hub position

Luc,

Could it be the normal slop from the input shaft & main shaft needle bearings where they mate together causing this rather than a hub doing this? I think I noticed the same thing on mine but was so minor. I let it go.

Could it be the normal slop from the input shaft & main shaft needle bearings where they mate together causing this rather than a hub doing this? I think I noticed the same thing on mine but was so minor. I let it go.

Dino Falabrino

On the "G" since 1998.

1943 GPW 102310 DOD 3-3-43

1928 Model A Roadster Pickup

1930 Model A Tudor

1968 Taco Minibike

On the "G" since 1998.

1943 GPW 102310 DOD 3-3-43

1928 Model A Roadster Pickup

1930 Model A Tudor

1968 Taco Minibike

-

Wolfman

- G-Lieutenant General

- Posts: 6906

- Joined: Sat Jan 12, 2008 5:25 am

- Location: Tipton,In.

Re: T84 neutral synchro hub position

The synchro hub has three bars in it that are held in place by two wire springs, one in the front of the hub and one in the rear. (You already know this).

The bars fit loosely in notches in the front and rear blocking rings.

The bars have a "bump" on top that fits into a notch inside the shift collar, when the shift collar s in neutral.

Helps hold the shift collar in the neutral position.

The bars and blocking rings can move slightly for and aft so the collar may being slightly out of position. Once the transmission spins up, it all centers up. No big deal. ( what Luc said )

If you take the transmission back apart, and you replaced the bars during the rebuild, look the bars over.

Some of the after market bars I have seen are junk.

The bars should be flat on top, with the bump in the top center pretty pronounced and the end tabs bent down squarely and the tabs not too long or short. And they should all be the same length.

Some of the bars I have encountered are " Hump Backed ", not flat on top. The bump was barely noticable. The radius of the bend, on the tabs on the end of the bars were very rounded. You don't want the radius to be too tight or the tab will break off, but you don't want the radius to be round as a golf ball either. Also, check the length of the tabs. The junk bar tab lengths are all over the place. The tab should only stick down slightly past the sides and all be the same length. Some of the junk bars I have seen, had tabs of all different lengths. Too long and too short.

One other point. Go up and check John Barton's sticky on rebuilding transmissions. I posted an alteration I make on the wire spring, inside the synchro hub, that holds the three bars in place. The wire spring originally has a bent ear on each end. One of these ears is placed into one of the bars in the hub. The other bent ear is just up against the inside of the hub and this holds the spring away from the third bar in the hub. Leaves bar 3 floating loose on one end. Not good. I cut this second ear off so the spring can fit up against the third tab and hold it inplace like it is suppose to. Also, I don't put the ear on each spring in the same tab, front and rear.

The bars fit loosely in notches in the front and rear blocking rings.

The bars have a "bump" on top that fits into a notch inside the shift collar, when the shift collar s in neutral.

Helps hold the shift collar in the neutral position.

The bars and blocking rings can move slightly for and aft so the collar may being slightly out of position. Once the transmission spins up, it all centers up. No big deal. ( what Luc said )

If you take the transmission back apart, and you replaced the bars during the rebuild, look the bars over.

Some of the after market bars I have seen are junk.

The bars should be flat on top, with the bump in the top center pretty pronounced and the end tabs bent down squarely and the tabs not too long or short. And they should all be the same length.

Some of the bars I have encountered are " Hump Backed ", not flat on top. The bump was barely noticable. The radius of the bend, on the tabs on the end of the bars were very rounded. You don't want the radius to be too tight or the tab will break off, but you don't want the radius to be round as a golf ball either. Also, check the length of the tabs. The junk bar tab lengths are all over the place. The tab should only stick down slightly past the sides and all be the same length. Some of the junk bars I have seen, had tabs of all different lengths. Too long and too short.

One other point. Go up and check John Barton's sticky on rebuilding transmissions. I posted an alteration I make on the wire spring, inside the synchro hub, that holds the three bars in place. The wire spring originally has a bent ear on each end. One of these ears is placed into one of the bars in the hub. The other bent ear is just up against the inside of the hub and this holds the spring away from the third bar in the hub. Leaves bar 3 floating loose on one end. Not good. I cut this second ear off so the spring can fit up against the third tab and hold it inplace like it is suppose to. Also, I don't put the ear on each spring in the same tab, front and rear.

Mike Wolford

CJ-2A

VEP GPW

Comm./Inst. SEL

AOPA ( 50 yrs)

EAA ( 49 yrs)

4th Inf. Div. - 5th Inf. Div. - 2nd Armor Div. - CIB

CJ-2A

VEP GPW

Comm./Inst. SEL

AOPA ( 50 yrs)

EAA ( 49 yrs)

4th Inf. Div. - 5th Inf. Div. - 2nd Armor Div. - CIB

-

Finn42

- Sergeant Major of the Gee

- Posts: 349

- Joined: Thu Jan 06, 2005 5:40 pm

- Location: Santa Rosa, CA

Re: T84 neutral synchro hub position

Thanks Dino, mike and luc, you guys are awesome. Short of shimming the front bearing out, I guess I’m done. I was always told that in neutral the fork had to be centered.(but that was by a guy who said put more Gaskets at the front snout to do this!). We all know what that would do- wobbly Input shaft much?

I like that you guys all say lock that front bearing down - it makes me wonder how ford had it—I have no visible signs of wear on snout or case and that gasket back on would allow me to bring the synchro hub .015 away from the fork. Did they just rely on the pilot bearing in the flywheel to center the input shaft I wonder and keep it from wobbling? Granted we are using new bearings that may measure thinner.

I like that you guys all say lock that front bearing down - it makes me wonder how ford had it—I have no visible signs of wear on snout or case and that gasket back on would allow me to bring the synchro hub .015 away from the fork. Did they just rely on the pilot bearing in the flywheel to center the input shaft I wonder and keep it from wobbling? Granted we are using new bearings that may measure thinner.

1942 GPW

1942 T2 wla

1942 Bantam

1942 WC40

1941 Nash-kelvinator Ben hur

1943 Ben Hur

1944 Ben hur

1942 T2 wla

1942 Bantam

1942 WC40

1941 Nash-kelvinator Ben hur

1943 Ben Hur

1944 Ben hur

- Chuck Lutz

- Gee Addict

- Posts: 26829

- Joined: Wed Jun 28, 2006 7:00 am

- Location: Jeep Heaven

Re: T84 neutral synchro hub position

After measuring a bunch of GPW front bearing retainers and finding that the snap ring on the bearing is held in place by it and that tolerance is almost EXACTLY the same on all of them.....I measured even MORE of the front bearing retainers found on the WG T84s only to find that tolerance was all over the place. This will allow not only some fore/aft "axial play" of the main gear....but it does nothing to prevent the possibility of the bearing spinning and wallowing out the opening in the T84 case.

As noted in many T84 threads, you can remove some material from the front bearing retainer to better immobilize the snap ring to hold the bearing in place and...if you have the original bearing, you can CAREFULLY remove it and replace it with the one that is thinner on most new bearings to help immobilize it!

As noted in many T84 threads, you can remove some material from the front bearing retainer to better immobilize the snap ring to hold the bearing in place and...if you have the original bearing, you can CAREFULLY remove it and replace it with the one that is thinner on most new bearings to help immobilize it!

Chuck Lutz

GPW 17963 4/24/42 Chester, PA. USA 20113473 (USA est./Tom W.)

Bantam T3-C 1947

GPW 17963 4/24/42 Chester, PA. USA 20113473 (USA est./Tom W.)

Bantam T3-C 1947

-

Finn42

- Sergeant Major of the Gee

- Posts: 349

- Joined: Thu Jan 06, 2005 5:40 pm

- Location: Santa Rosa, CA

Re: T84 neutral synchro hub position

Hi chuck

So my Gpw retainer holds the snap ring(original) with a new bearing almost even with the surface of the retainer. The snap ring is maybe .003 shy- allowing a slight movement. I’d like to lock it down more. Were the original roller bearings wider? If I put a gasket in like the factory it will wobble big time.

So my Gpw retainer holds the snap ring(original) with a new bearing almost even with the surface of the retainer. The snap ring is maybe .003 shy- allowing a slight movement. I’d like to lock it down more. Were the original roller bearings wider? If I put a gasket in like the factory it will wobble big time.

1942 GPW

1942 T2 wla

1942 Bantam

1942 WC40

1941 Nash-kelvinator Ben hur

1943 Ben Hur

1944 Ben hur

1942 T2 wla

1942 Bantam

1942 WC40

1941 Nash-kelvinator Ben hur

1943 Ben Hur

1944 Ben hur

- artificer

- banned

- Posts: 13558

- Joined: Tue Jul 11, 2006 10:46 am

- Location: SINGAPORE

Re: T84 neutral synchro hub position

Please explain what you are saying as it doesn't sound right. Pics or diagram would be good.Finn wrote:My input shaft has an original circlip albeit I had to forgo using a seal because the snout is level with the clip.

In N the shift forks should not be in anyway loaded on 1/R gear or 2/3 sliding sleeve slots.

John GIBBINS Member Institute of Automotive Mechanical Engineers [Ret], ASE Master Medium/Heavy Truck & Auto Technician USA -2002 Licensed Motor Mech NSW MVIC 49593 Current 2015

TO DIAGNOSE, TROUBLESHOOT OR FAULT FIND ANY AUTO SYSTEM....

Understand how system parts interact with one another. GOOD parts can then be established & the NOT GOOD problem/s part/s isolated for repair or replacement.

TO DIAGNOSE, TROUBLESHOOT OR FAULT FIND ANY AUTO SYSTEM....

Understand how system parts interact with one another. GOOD parts can then be established & the NOT GOOD problem/s part/s isolated for repair or replacement.

-

Finn42

- Sergeant Major of the Gee

- Posts: 349

- Joined: Thu Jan 06, 2005 5:40 pm

- Location: Santa Rosa, CA

Re: T84 neutral synchro hub position

1942 GPW

1942 T2 wla

1942 Bantam

1942 WC40

1941 Nash-kelvinator Ben hur

1943 Ben Hur

1944 Ben hur

1942 T2 wla

1942 Bantam

1942 WC40

1941 Nash-kelvinator Ben hur

1943 Ben Hur

1944 Ben hur

- artificer

- banned

- Posts: 13558

- Joined: Tue Jul 11, 2006 10:46 am

- Location: SINGAPORE

Re: T84 neutral synchro hub position

Regarding leaving out the seal. If you are talking about the cork seal or the felt rubber type & not using a sealed bearing you will have a very bad oil leak. The felt type is too thick for the T84 & needs modification.

John GIBBINS Member Institute of Automotive Mechanical Engineers [Ret], ASE Master Medium/Heavy Truck & Auto Technician USA -2002 Licensed Motor Mech NSW MVIC 49593 Current 2015

TO DIAGNOSE, TROUBLESHOOT OR FAULT FIND ANY AUTO SYSTEM....

Understand how system parts interact with one another. GOOD parts can then be established & the NOT GOOD problem/s part/s isolated for repair or replacement.

TO DIAGNOSE, TROUBLESHOOT OR FAULT FIND ANY AUTO SYSTEM....

Understand how system parts interact with one another. GOOD parts can then be established & the NOT GOOD problem/s part/s isolated for repair or replacement.

-

Finn42

- Sergeant Major of the Gee

- Posts: 349

- Joined: Thu Jan 06, 2005 5:40 pm

- Location: Santa Rosa, CA

Re: T84 neutral synchro hub position

I was referring to the big paper gasket that goes on the front

1942 GPW

1942 T2 wla

1942 Bantam

1942 WC40

1941 Nash-kelvinator Ben hur

1943 Ben Hur

1944 Ben hur

1942 T2 wla

1942 Bantam

1942 WC40

1941 Nash-kelvinator Ben hur

1943 Ben Hur

1944 Ben hur

-

Wolfman

- G-Lieutenant General

- Posts: 6906

- Joined: Sat Jan 12, 2008 5:25 am

- Location: Tipton,In.

Re: T84 neutral synchro hub position

I have run into gasket sets with all different thickness front retainer gaskets. On early OEM sets, this gasket actually covered the entire front of the transmission. Was between the bellhousing and retainer. Have not seen one of those gaskets in a long time.

There needs to some sort of seal between the retainer and transmission. You can't just leave the gasket out.

I have run into loose snap rings under the retainer and to tighten those up, I used 3M Ultra Black silione gasket maker to seal the retainer instead of a gasket. Gives a tighter fit and still seals. Don't over do it. You do not want to block the oil drain hole.

But to take this a little farther, I have seen front retainers, that when fit to the transmission, the snap ring was thick enough to hold the retainer away from the transmission front. You had to use a correct thickness gasket.

Comes down to the assembler checking things like this to get it right.

Felt seal ? Seems to me some one said the thick felt seals, with felt on either side of a rubber washer was for another transmission. Not a T-84.???

Any one recall this ??

The solution. Cut the felt off one side of the center rubber washer. Now the seal is thinner and does not fit so tight but still seals. Rubber side goes against the bearing.

As for the synchro spring, it is what I do. Just sharing.

Try to have a reason for everything.

T-84 transmission in GPW 964.

Barely had it drivable when the transmission would not shift into 3rd gear. What I found was, one of the three bars had popped up, keeping the shift collar from moving forward. The reason, I determined, was the spring with the ear was not holding that end of the bar that popped up in place. I cut one ear off of both springs , as I described and have not had this happen since. And I do this to all my rebuilds. They have not had this issue either.

One more thought, The bent down tab, on the end of the bar, does need to be slightly longer than the bar sides. Keeps the spring from coming off.

What I do but, builder's choice.

There needs to some sort of seal between the retainer and transmission. You can't just leave the gasket out.

I have run into loose snap rings under the retainer and to tighten those up, I used 3M Ultra Black silione gasket maker to seal the retainer instead of a gasket. Gives a tighter fit and still seals. Don't over do it. You do not want to block the oil drain hole.

But to take this a little farther, I have seen front retainers, that when fit to the transmission, the snap ring was thick enough to hold the retainer away from the transmission front. You had to use a correct thickness gasket.

Comes down to the assembler checking things like this to get it right.

Felt seal ? Seems to me some one said the thick felt seals, with felt on either side of a rubber washer was for another transmission. Not a T-84.???

Any one recall this ??

The solution. Cut the felt off one side of the center rubber washer. Now the seal is thinner and does not fit so tight but still seals. Rubber side goes against the bearing.

As for the synchro spring, it is what I do. Just sharing.

Try to have a reason for everything.

T-84 transmission in GPW 964.

Barely had it drivable when the transmission would not shift into 3rd gear. What I found was, one of the three bars had popped up, keeping the shift collar from moving forward. The reason, I determined, was the spring with the ear was not holding that end of the bar that popped up in place. I cut one ear off of both springs , as I described and have not had this happen since. And I do this to all my rebuilds. They have not had this issue either.

One more thought, The bent down tab, on the end of the bar, does need to be slightly longer than the bar sides. Keeps the spring from coming off.

What I do but, builder's choice.

Mike Wolford

CJ-2A

VEP GPW

Comm./Inst. SEL

AOPA ( 50 yrs)

EAA ( 49 yrs)

4th Inf. Div. - 5th Inf. Div. - 2nd Armor Div. - CIB

CJ-2A

VEP GPW

Comm./Inst. SEL

AOPA ( 50 yrs)

EAA ( 49 yrs)

4th Inf. Div. - 5th Inf. Div. - 2nd Armor Div. - CIB

- Chuck Lutz

- Gee Addict

- Posts: 26829

- Joined: Wed Jun 28, 2006 7:00 am

- Location: Jeep Heaven

Re: T84 neutral synchro hub position

Many gasket sets sole for the T84 are designed to also be used on the T84. Ron has custom made gasket sets designed for the T84 which have a front bearing retainer gasket that is 0.014" (GPW) or 0.016" (Willys) thick...I'm not sure which, but they are the correct thickness to use.

The black, thick ones sold in some gasket sets are WAY too thick and I think what you may have. Don't use them, use the THIN ones and a sealed-both-sides bearing with an original THICKER snap ring and seal it like artificer suggests but only use the sealer AFTER you have set the spacers and are positive you have correct "slop" on both blocking rings and it will shift once you put the tower/shift can on it for a bench test. Be sure you at least put SOME gear oil on the components prior to assembly to enable you to shift it! THEN remove the front bearing retainer and use the sealant and put it together.

The black, thick ones sold in some gasket sets are WAY too thick and I think what you may have. Don't use them, use the THIN ones and a sealed-both-sides bearing with an original THICKER snap ring and seal it like artificer suggests but only use the sealer AFTER you have set the spacers and are positive you have correct "slop" on both blocking rings and it will shift once you put the tower/shift can on it for a bench test. Be sure you at least put SOME gear oil on the components prior to assembly to enable you to shift it! THEN remove the front bearing retainer and use the sealant and put it together.

Chuck Lutz

GPW 17963 4/24/42 Chester, PA. USA 20113473 (USA est./Tom W.)

Bantam T3-C 1947

GPW 17963 4/24/42 Chester, PA. USA 20113473 (USA est./Tom W.)

Bantam T3-C 1947

- Chuck Lutz

- Gee Addict

- Posts: 26829

- Joined: Wed Jun 28, 2006 7:00 am

- Location: Jeep Heaven

Re: T84 neutral synchro hub position

English is not exactly the same the world around...

Hood = Bonnet

Trunk = Boot

Snap Ring = Circlip (?)

Blocking Ring = Baulking Ring

In some places they even drive on the wrong side of the road if you can believe it!

However, here in the US of A, I suggest the American version of identification as found in the manuals would not make some posts so confusing to others.

Hood = Bonnet

Trunk = Boot

Snap Ring = Circlip (?)

Blocking Ring = Baulking Ring

In some places they even drive on the wrong side of the road if you can believe it!

However, here in the US of A, I suggest the American version of identification as found in the manuals would not make some posts so confusing to others.

Chuck Lutz

GPW 17963 4/24/42 Chester, PA. USA 20113473 (USA est./Tom W.)

Bantam T3-C 1947

GPW 17963 4/24/42 Chester, PA. USA 20113473 (USA est./Tom W.)

Bantam T3-C 1947

-

Wolfman

- G-Lieutenant General

- Posts: 6906

- Joined: Sat Jan 12, 2008 5:25 am

- Location: Tipton,In.

Re: T84 neutral synchro hub position

You hit on one more point that may easily slip by unnoticed, Chuck.

The fit of the snap ring on the front bearing. Thick snap rings and thin snap rings.

I have run across front bearings with a thin snap ring. The ring was loose in it's groove in the outer bearing race. No matter how tight the ring fit in the retainer, it could still move in the bearing. The input shaft would have for and aft play you could not get rid of.

The fit of the snap ring on the front bearing. Thick snap rings and thin snap rings.

I have run across front bearings with a thin snap ring. The ring was loose in it's groove in the outer bearing race. No matter how tight the ring fit in the retainer, it could still move in the bearing. The input shaft would have for and aft play you could not get rid of.

Mike Wolford

CJ-2A

VEP GPW

Comm./Inst. SEL

AOPA ( 50 yrs)

EAA ( 49 yrs)

4th Inf. Div. - 5th Inf. Div. - 2nd Armor Div. - CIB

CJ-2A

VEP GPW

Comm./Inst. SEL

AOPA ( 50 yrs)

EAA ( 49 yrs)

4th Inf. Div. - 5th Inf. Div. - 2nd Armor Div. - CIB